Michaela Varnier, EI, Project Specialist with Red Rock Consulting, recently discovered the joys of drilling within a suspected TCE plume at Vance Air Force Base in Enid, Oklahoma.

Michaela at Vance AFB in Enid, OK

Michaela Varnier, EI, Project Specialist with Red Rock Consulting, recently discovered the joys of drilling within a suspected TCE plume at Vance Air Force Base in Enid, Oklahoma.

Michaela at Vance AFB in Enid, OK

In June, 2010 Red Rock Consulting was certified as a Building Resources In Developing & Growing Enterprises (BRIDGE) business by the City of Tulsa.

The City of Tulsa’s BRIDGE program is much like ODOT’s DBE program, where larger firms are encouraged to use firms owned by minorities and women. ODOT and the City of Tulsa frequently specify a percentage of a project must utilize DBE/BRIDGE certified companies when possible.

A recent project site in Tulsa, Oklahoma.

Red Rock Consulting and DSO recently completed two projects in Tulsa, Oklahoma. One was a commercial development and the other was a municipal pavement project.

Our team travels all over Oklahoma and north Texas to provide geotechnical engineering services. We have worked from Woodward, Oklahoma to Marshall, Texas and many places in between.

Kristi Bumpas (RRC) and Todd Simpson (DSO) at a project site in Tulsa, June 2010

Red Rock Consulting would like to thank all veterans for their selfless contributions to our country and our freedom. Happy Memorial Day!

Hey all! Please check out the “About” section of this website. I just updated my resumes and put them up. Let me know if you need a resume for another project type. Happy Monday!

Dr. Jim Nevels takes samples for a pedological project.

Hard at work in Edmond

Red Rock Consulting and DSO recently completed a project at Vance Air Force Base in Enid, Oklahoma, that had special requirements. US Army Corps of Engineers required the geotechnical team to core bedrock materials. The Corps also requested that environmental precautions be taken because the project site was located within the base’s trichloroethylene (TCE) plume.

Rock coring is not a standard procedure in many parts of Oklahoma. It requires that the rock be drilled using wet rotary methods.

Wet Rotary Drilling

Core Barrel

Core Sample

In addition to coring bedrock, the auger and wet rotary soil cuttings had to be contained in a drum. Soil samples were then sent to an environmental laboratory to be tested for contamination. The lab results will determine how the drum of soil will be disposed of.

Placing Suspected Contaminated Soil into Drum

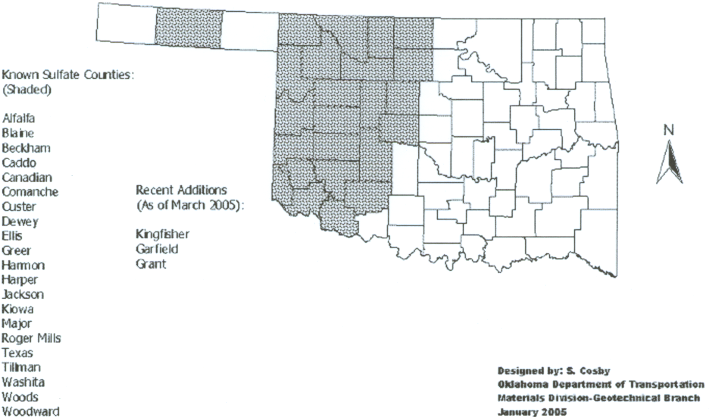

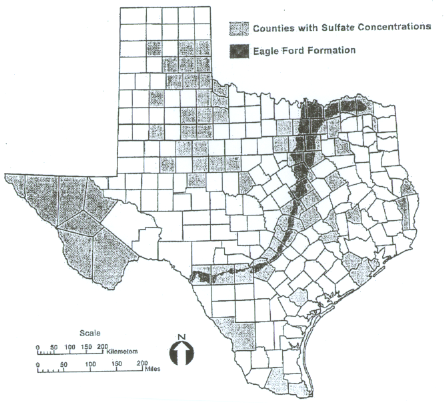

The Oklahoma Department of Transportation (ODOT) and the Texas Department of Transportation (TexDOT) keep a record of known sulfate counties in their respective states.

These are counties where sulfates have been verified through laboratory testing and/or sulfate heave has been a problem in the past. These maps of known sulfate occurrences are helpful for the government agencies and consultants who may have projects in the areas. If sulfates have been found in or near their project area, sulfate testing and/or preventative measures in design can be taken.

The sulfates counties for Oklahoma and Texas are shown below, courtesy of ODOT and TexDOT (Harris, Sebesta, Scullion, 2004).

Sulfate Counties in Oklahoma

Sulfate Counties in Texas

Commercial and residential projects in Oklahoma do not require on-site geotechnical engineering. Most geotechnical firms do not provide on-site engineering in their normal scopes of work and fee proposals. Because of this, many geotechnical engineers never see the site of the project they are providing recommendations for. Red Rock Consulting always recommends on-site engineering and provides it on each project unless a special exception has been agreed upon with the client for a specific project.

Geotechnical engineering recommendations are site specific for every project. Physically observing the site, the surroundings and the subsurface materials as they come out of the ground is crucial to providing the best recommendations for the project.

Marking Boring Locations

Geotechnical borings should be located on-site by the engineer. The geotechnical engineer is the only person who has been in contact with the client and with direct knowledge of the project objectives, constraints and concerns. In addition, the geotechnical engineer is the only person who has communicated with the utility locators.

Many sites have obstructions or other reasons why the borings cannot be located at the preferred locations. With a geotechnical engineer on site the decision is made with the proposed project in mind by an engineer familiar with the project and needs of the client.

Field Logs

A geotechnical engineer on-site should always log the borings as the drilling is taking place. In this case, the drill crew is allowed to focus on the equipment and the “feel” of the subsurface conditions as the borings are advanced. The geotechnical engineer should communicate with the drill crew regarding drilling, field testing and subsurface conditions and observe and log the soil samples as they are produced.

When a geotechnical engineer logs the borings, site specific questions can be addressed more quickly. Changes in boring depth and sampling of special soil conditions, which are both discussed below, are two examples of on-site issues that may arise on a project.

Occasionally borings need to be advanced to a different depth than planned due to encountering unanticipated subsurface materials, such as deep or shallow bedrock or very soft materials, for example. With a geotechnical engineer on site, the decision to extend or terminate the boring can be made without having to return to the site, which would result in additional mobilization and soil drilling charges.

Communicating with Drillers

Oklahoma has a number of soil conditions which can be identified on site by a trained geotechnical engineer. Two examples of such soils are expansive soils and sulfate rich soils, both of which can be detrimental to construction projects if left unidentified. A geotechnical engineer, who is on the project site and observing the soil, can identify these problematic soils immediately and have them tested in order to provide proper recommendations to combat such soils.

The best geotechnical engineering reports are those written by engineers who know the project objectives and who have seen the project site first hand. The report is written specifically for the site that was observed and the soil conditions encountered. In addition, if any questions arise during design and/or construction, the geotechnical engineer can provide informed solutions as a result of the on–site experience during the geotechnical investigation.

You are currently browsing the archives for the Uncategorized category.

Arclite theme by digitalnature | powered by WordPress